Factors affecting the efficiency of lemongrass essential oil production in Vietnam

(Information summarized from the Research Article: “STUDY ON EXTRACTION PROCESS, CHEMICAL COMPOSITION AND ANTIBACTERIAL EFFECTS OF LEMONGRASS ESSENTIAL OIL (Cymbopogon citratus (DC.) Staft – Poaceae)” was carried out by the authors Authors: Nguyen Thi Thanh Huong, Nguyen Trong Hieu, Nguyen Phan Dong Anh, Ngo Thi Tuyet Mai, Le Thi Bich Hien – Faculty of Pharmacy, Hue University of Medicine and Pharmacy)

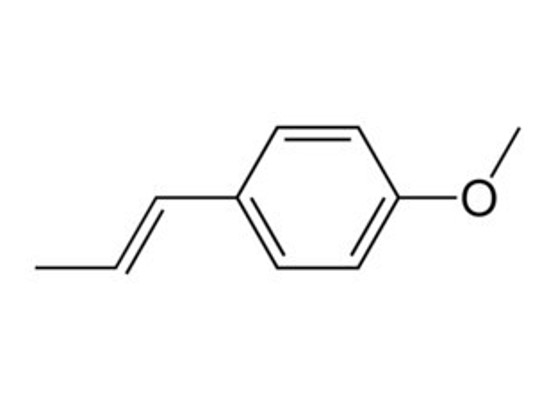

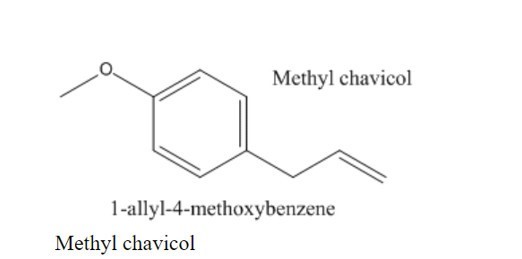

Vietnamese lemongrass has the scientific name Cymbopogon Citratus and belongs to the Poaceae family. This is a plant that easily lives in harsh conditions, grows in bushes, with a height of 80cm to 1m. Unlike Citronella grass, lemongrass has a white, slightly purple stem, often used as a spice in cooking. It takes about 6 months from planting lemongrass to harvesting. Essential oil content is about 0.25% – 0.3%. In addition to its use as a spice, lemongrass is also a raw material for distilling essential oils. Vietnamese lemongrass essential oil has the main ingredient Citral, accounting for over 75% (including α-citral and β-citral). Lemongrass essential oil is widely used in cosmetics, medicine, flavor and fragrance…

In Vietnam, lemongrass is grown in many places, especially in many mountainous areas, lemongrass has been planned to be grown as a raw material for distilling essential oils.

Factors affecting the efficiency of lemongrass essential oil production include: extraction time, solvent-raw material ratio, raw material harvesting time, post-harvest distillation time. The volume of raw materials used for the survey is 1 kg of lemongrass (stem and leaves). Optimal distillation conditions are based on the volume of essential oil obtained. Results and conclusions about factors affecting the effectiveness of lemongrass essential oil production are as follows:

1. Physical indicators of lemongrass essential oil

Lemongrass essential oil liquid, color from transparent to light yellow, has the characteristic aroma of lemongrass. High quality lemongrass essential oil has the following physical indicators:

– Specific Gravity: 0.872 – 0.897

– Refractive Index: 1.483 – 1.489

– Optical Rotation: -3o –> 1o

2. Factors affecting the production process of lemongrass essential oil.

2.1 Distillation time.

| Time | 90 minutes | 120 minutes | 150 minutes | 180 minutes | 210 minutes | 240 minutes |

| Amount of essential oil (ml) | 3,20 ±0,10 | 3,53 ±0,06 | 3,87 ±0,06 | 3,93 ±0,06 | 4,00 ±0,1 | 4,00 ±0,1 |

| Content % (ml/100g) | 0,32±0,01% | 0,35±0,01% | 0,39±0,01% | 0,39±0,01% | 0,40±0,01% | 0,40±0,01% |

Results in Table 1 show that the essential oil content obtained after distillation for 150 minutes is higher than for distillation time of 90 minutes and 120 minutes. Distillation time longer than 150 minutes gives a slightly higher essential oil content, but the small increase is not statistically significant. Thus, the optimal time is 150 minutes.

2.2 Solvent – raw material ratio

| Ration | 4:1 | 5:1 | 6:1 | 7:1 |

| Amount of essential oil (ml) | 3,67 ± 0,11 | 4,13 ± 0,06 | 4,17 ± 0,10 | 4,17 ± 0,06 |

| Content % (ml/100g) | 0,37±0,01% | 0,41±0,01% | 0,42±0,01% | 0,42±0,01% |

The results in Table 2 show that the volume of essential oil gradually increases with the solvent-raw material ratio. When increasing this ratio to 5:1, 6:1 and 7:1, the essential oil content obtained gradually increased but the difference was not statistically significant. Thus, the optimal solvent-raw material ratio is 5:1. Accordingly, can both obtain the largest volume of essential oil and save fuel and solvents used for the distillation processing.

2.3 Time to harvest raw materials.

| Month | Amount of essential oil (ml) | Content % (ml/100g) | Month | Amount of essential oil (ml) | Content % (ml/100g) |

| 1 | 3,60 ±0,10 | 0,36±0,01 | 7 | 3,73 ±0,21 | 0,37±0,02 |

| 2 | 3,63 ±0,21 | 0,36±0,02 | 8 | 3,70 ±0,10 | 0,37±0,01 |

| 3 | 4,17 ±0,06 | 0,42±0,01 | 9 | 3,33 ±0,06 | 0,33±0,01 |

| 4 | 4,13 ±0,06 | 0,41±0,01 | 10 | 3,33 ±0,06 | 0,36±0,02 |

| 5 | 3,60 ±0,10 | 0,36±0,01 | 11 | 3,87 ± 0,06 | 0,39±0,01 |

| 6 | 3,37 ±0,06 | 0,34±0,01 | 12 | 3,90 ± 0,10 | 0,39±0,01 |

The results of surveying the influence of harvest time on essential oil content are shown in Table 3. Accordingly, the highest amount of essential oil is obtained when harvesting raw materials in March or April (0.41–0 .42%). The amount of essential oil obtained when extracted in these 2 months is statistically different from the remaining months. Therefore, the recommended time to harvest lemongrass plants during the year is March or April.

2.4 Post-harvest distillation time.

Survey results show that essential oil content gradually decreases with time after harvest. The amount of essential oil obtained when extracted on the first day after harvest is the highest (reaching 0.4%), the longer it is stored, the more essential oil content will be lost. Therefore, to achieve high efficiency, it should distill lemongrass essential oil as soon as the raw materials are harvested.

3. Conclusion

Thus, it was possible to determine the optimal conditions for extracting lemongrass essential oil in Vietnam (the resulting essential oil content is about 0.40 – 0.42%). The most effective distillation conditions include: raw materials collected in March or April every year, distilling for 2.5 hours, solvent – raw material ratio 5:1, required Immediately distill raw materials that have just been harvested that day.

Harvest time greatly affects the essential oil content in lemongrass, so calculating the harvest time is important in large-scale production applications. In addition, appropriate distillation time and solvent-raw material ratio help reduce production costs. Distilling immediately after harvest helps avoid loss of essential oils, especially if storage conditions are not good. Moisture can reduce the volume of produced essential oil and sometimes reduce the quality of essential oil by affecting the content of constituents. In summary, the above optimal conditions will contribute to the application of essential oil distillation on a larger scale to achieve high essential oil content and quality while saving fuel and production time.

4. Lemongrass essential oil produced at VIPSEN essential oil factory.

VIPSEN is one of the leading researchers and producers of natural essential oils in Vietnam. Essential oil products are produced using advanced methods, achieving high quality with 100% natural ingredients, without additives or mixtures.

Lemongrass essential oil products are produced by VIPSEN from selected raw materials, grown in famous and sustainable growing areas in Vietnam such as Tuyen Quang, Ha Nam, Thanh Hoa… Production process from planting, harvesting to producing and preserving finished products are always closely monitored by team of experienced experts and technicians. VIPSEN’s Lemongrass essential oil products are not only popular in Vietnam but are also exported to many countries around the world.

For more information, please contact:

Phone/Whatsapp/Zalo/Wechat/Kakao Talk/Line/Skype/Viber: +84 868 855 086

Email: Tony@Vipsen.vn

Address: D7-TT9, Forosa Street, Xuan Phuong New Urban Area, Xuan Phuong, Nam Tu Liem, Hanoi

Address of essential oil factory: Bai Dai, Tien Xuan, Thach That, Hanoi, Vietnam

Address of ginger and star anise factory: Thu Do, An Tuong, Vinh Tuong, Vinh Phuc, Vietnam